Specialized in aluminum castings for automotive, electric cars, 5G and new energy industries.

Precision, high strength, high airtightness, high wear resistant structural parts, valve bodies, flanges, connectors, etc.

One-stop aluminum die casting solutions, in-house mold making, competitive pricing, fast delivery, ISO9001 & IATF16949.

Squeeze casting, also known as liquid metal forging, is a combination of die casting and forging processes, and has the advantages of both.

Squeeze casting can effectively eliminate common aluminum die casting defects, such as porosity or shrinkage, to get a more dense and uniform internal grain. Moreover, squeeze casting parts can be heat-treated to further improve the mechanical properties of the parts.

Squeeze casting is more efficient than sand casting, gravity casting or low pressure die casting, and less costly than forging process or CNC machining.

When you choose a die casting process for demanding industries such as automotive, electric vehicles, aerospace, etc., squeeze casting is your ideal choice!

1. Lower Porosity, Higher Density, Highter Strenth, Higher Airtightness

2. Can be Heat Treated and Welded

3. Excellent Mechanical Properties:

Tensile Strength: 260-330 MPa

Yield Strength: 220-280 MPa

Elongation: 8%-13%

Hardness: 90-115Hb

Air Tightness: ≥0.5MPa

As a professional aluminum die casting company, SANON CASTING provides one-stop solutions from rapid prototyping to surface treatment of parts. You can get excellent aluminum die casting quality and fast delivery from us, and it will be stable!

After you have completed the product design, we have two ways to help you quickly get feedback on the product design, and to evaluate and justify the feasibility of the product design.

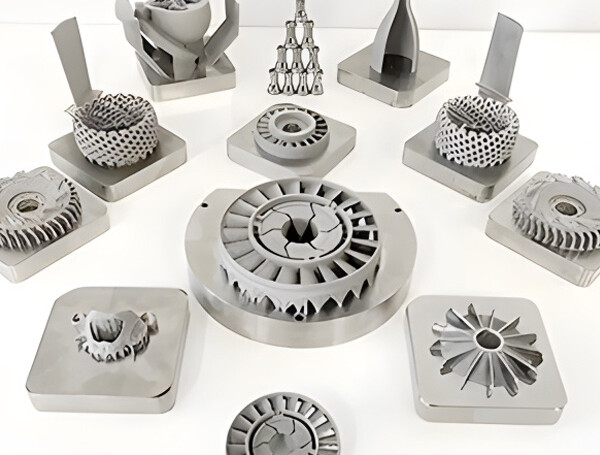

3D printing: Lowest cost, fastest delivery, suitable for all kinds of metals and plastics.

CNC machining: Our lathes, milling machines, CNC machining centers, and experienced operators can get your precision parts to you faster.

Die casting molds determine the shape, tolerances, surface and internal filling of the part with molten metal. Dies are critical in your aluminum die casting project, so when you are looking for an aluminum die casting manufacturer, you’d better choose one with a mold making shop, especially if your parts are complex or your die casting project is urgent.

SANON CASTING has 22 years of experience in die casting mold manufacturing, which is our earliest business. We have our own mold shop and have done 10000+ die casting molds for different industries. Mold design experience is our great advantage, moreover, we also provide free mold modification and maintenance.

As a professional aluminum die casting manufacturer, we are proficient in 3 different aluminum die casting processes: High Pressure Die Casting (HPDC), Low Pressure Die Casting (LPDC) and Squeeze Casting. These 3 die casting processes can meet almost any of your aluminum die casting project needs.

HPDC: For light weight, thin walled, complex shapes, precision, large volume aluminum castings;

LPDC: For heavy, thick walled, simple shapes, high strength aluminum castings;

Squeeze Casting: For complex shapes, precision, high air tightness, high strength aluminum castings.

The normal aluminum die casting process can’t be heat treated, but squeeze casting can. After heat treatment, the squeeze casting parts can greatly improve the strength and air tightness of the parts.

For example, the commonly used squeeze casting aluminum alloy is A356.2, which after T5 heat treatment, the tensile strength of the part can reach 240 MPa, the yield strength can reach 270 MPa, the hardness can reach 90Hb, and the airtightness can be more than 0.5 MPa.

If your die castings need high strength, high air tightness, high wear resistance, then please do not hesitate to contact us!

If a die casting manufacturer does not have its own CNC processing workshop, it will be difficult for them to ensure the delivery time and quality of molds and parts. But at SANON you don’t have to worry about that.

We have our own lathes, milling machines and CNC centers, which are dedicated to our mold making and die casting processing. This ensures that we have a fast and stable delivery time that is not affected by external factors.

Our CNC machining experience is more than 12 years, and our machining accuracy can reach 0.01mm. we are capable of both large mold making and precision parts machining.

SANON has specialized surface finishing workshop for grinding, shot blasting and polishing. We can meet most of the surface treatment requirements for aluminum die casting parts, which can give your parts a better appearance.

If you have more surface requirements, our outsourced suppliers that we have worked with for many years can provide the following surface finishing processes:

Sandblasting, anodizing, powder coating, electroplating (chrome plating), electrophoresis.

More than 20 years of experience in aluminum die casting has given us a deeper understanding of our customers’ needs. We understand your product design concepts and know better how to provide you with high quality aluminum die castings.

Mold making is the most important part of the entire die casting process. The biggest assets of a die-casting factory are the mold design team and mold making workshop. We have our own tooling team and mold making workshop and have made over 10,000 molds. And, we provide free mold repair and maintenance!

We can use the aluminum squeeze casting process to solve common casting defects such as shrinkage and porosity. If your parts require high density, high strength, high hardness, and high air tightness, we can excellently achieve these requirements that ordinary die casting process cannot reach!

We provide one-stop solutions for aluminum die casting, from mold manufacturing to surface treatment. Our experienced team, advanced equipment, innovative die-casting technology, and win-win cooperation concept with customers make stable quality and delivery a reality, and have become our very obvious advantages!

As an aluminum die casting factory, we are committed to providing high quality precision aluminum die casting products to customers in different industries, such as automotive, electric vehicle, medical, machinery, electric power, telecommunication, home appliance and so on.

We are looking forward to cooperating with you, and we will provide you with reliable aluminum die casting parts with our experienced engineers, advanced aluminum die casting process and strict quality control system. If you need any aluminum die casting service, please feel free to contact us.