Injection Molding Capabilities

Injection Molding Materials

| Acrylonitrile Butadiene Styrene (ABS) | Polyamide os Nylon (PA12) | Polyamide os Nylon (PA6) | Polyamide os Nylon (PA66) |

| Polycarbonate (PC) | Polyoxymethylene (POM) | Polyether Ether Ketone (PEEK) | High Density Polyethylene (HDPE) |

| Low Density Polyethylene (LDPE) | Polyvinyl Chloride (PVC) | Poly(methyl methacrylate) (PMMA) | Polyphenylene Ether (PPE) |

| Polypropylene (PP) | Polystyrene (PS) | Thermoplastic Elastomers (TPE) | Acrylonitrile Styrene (AS) |

| Polyphenylene Sulfide (PPS) | Thermoplastic Polyurethane (TPU) | Nitrile Butadiene Rubber (NBR) | ...... |

Plastic Surface Treatment

Spraying

Spraying can make injection molded parts show different colors and effects, and can also increase the wear resistance, corrosion resistance and dustproof performance of injection molded parts.

Electroplating

It allows plastic parts to obtain metal-effect surfaces at higher yields and lower costs. Electroplating also allows plastic parts to increase their resistance to oxidation, corrosion and electrical conductivity.

Printing

Printing can make the surface of injection molded parts show rich patterns and colors. Pad printing, Screen printing and Transfer Printing are three commonly used printing methods.

Laser Carving

It is a process of surface treatment with optical principle. Through laser engraving can be typed or patterned on the surface of plastic parts.

As Your Request

We will choose the appropriate surface treatment process according to the drawings or your specific requirements to better realize the function of the part.

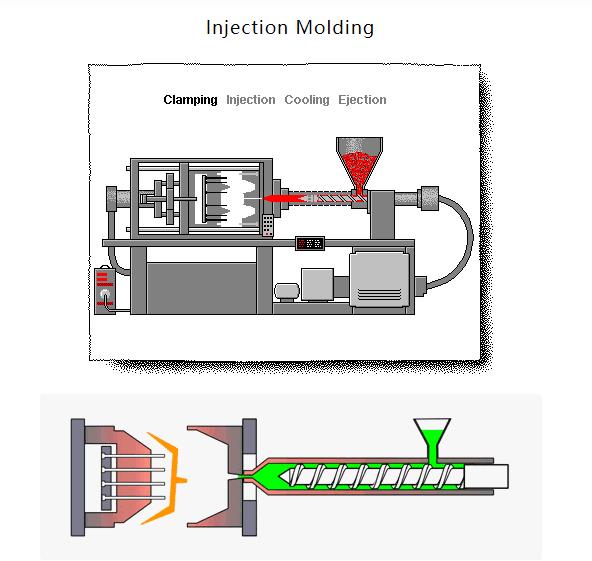

Plastic Injection Molding

Metal is not the only material that can be cast, plastic can also be cast.

In this process, the plastic is placed into a hopper, which then heats the plastic and injects it, which is pushed through a long chamber with a reciprocating screw.

Afterwards, the plastic is softened to a fluid state. The nozzle is located at the end of the chamber and the fluid plastic is forced through the nozzle to cool and close the mold.

As the plastic cools and cures, the semi-finished product is pushed out of the mold.

Plastic Injection Molding

If you are looking for a reliable injection molding manufacturer, and if you want your injection molding project to have stable high quality and fast delivery, please contact us.