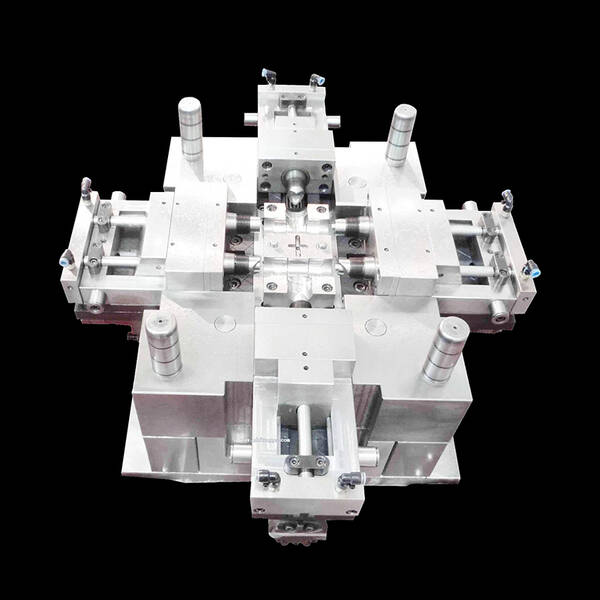

An Important Part of Casting-Mold Making

Sanon ‘s earliest business is mold making. We have 22 years of mold development and manufacturing experience.

The mold we developed has good strength, hardness, oxidation resistance and tempering stability. At the same time, it has high production efficiency and service life.

We can produce casting parts with precise dimensions to fully meet its functional requirements.

The Function of Mould

Casting mold is an important process equipment for die casting production. Whether the production process can be completed successfully and whether the die casting parts quality can be guaranteed depends largely on whether the mold structure is reasonable and whether the mold technology is advanced. Die casting mold has the following functions :

1, Determines the shape and size tolerance grade of the casting ;

2, The gating system, especially the gate location determines the filling status of molten metal ;

3, The exhaust system affects the molten metal slag discharge conditions’

4, Control and adjust the heat balance of die casting process ;

5, Determines the surface quality and deformation degree of castings ;

6, Determines the efficiency of die casting production

Some of The Molds We Have Developed

Several Typical Problems about Casting Mould

What are the common types of casting molds ?

Sand casting: wood moulds, resin sand moulds, aluminum alloy moulds

Gravity casting: steel moulds

Investment casting: wax mould

Disappearing mould casting: foam mould

Die casting: steel mould

Can the molds that we have developed be used in your factory?

Of course you can. But before we use it, we have to test the mold to make sure there is nothing wrong with it. Only then can we use this mold to cast your parts with confidence.

How long does it take to make a die-casting mold ?

20 to 35 days.

What is the service life of die casting moulds?

Generally, the service life of aluminum die casting molds is between 50,000 and 120,000 times. The service life of die mainly depends on material, structure design, heat treatment and post maintenance. The die-casting moulds have long production cycle, high manufacturing accuracy and expensive cost, so please make sure you find a factory with advanced technology for mould making.