What Can We Do For You in Rapid Prototyping ?

FDM-Fused Deposition Modeling

Forming material : Filamentous thermoplastic materials, PLA, ABS,TPU,PA(nylon),etc

Forming precision : ±0.1mm

Layer thickness : 0.06-0.4mm

Product characteristic : Low cost of materials, optional variety.

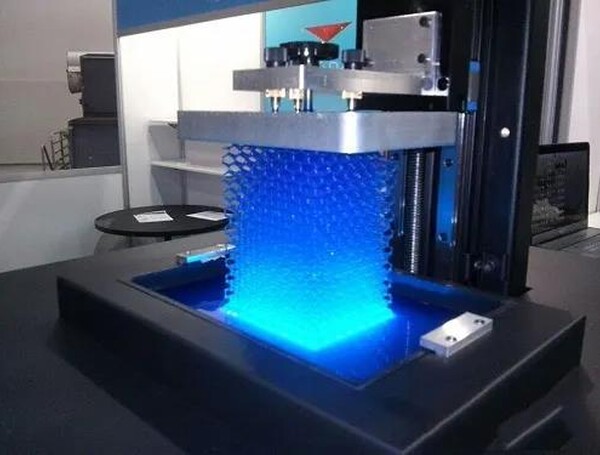

SLA-Stereo lithography Appearance

Forming material : Liquid photosensitive resin

Forming precision : ±0.1mm(L≤100mm)

Layer thickness : 0.05-0.2mm

Product characteristic : Fast forming speed, high precision, low cost, large size

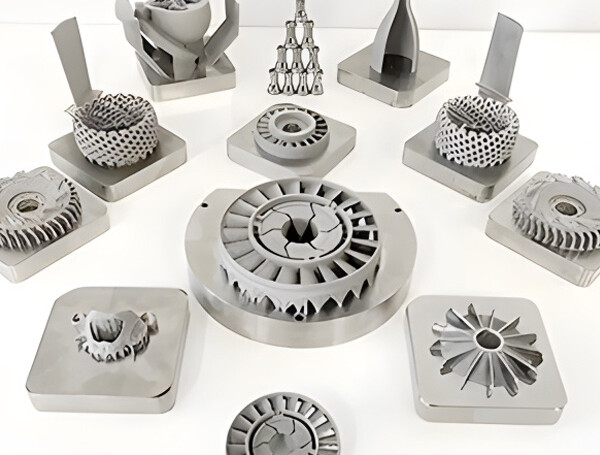

SLS-Selected Laser Sintering

Forming material :

Plastic powder,such as PA,PC,PEEK,etc

Metal powder, such as aluminum alloy, titanium alloy, stainless steel, mold steel

Forming precision : ±0.2mm(L≤200mm)

Layer thickness : 0.08-0.3mm

Product characteristic : Good mechanical properties, high strength.

3DP--Three Dimensional Printing

Forming material :

Plastic powder,such as PA,PC,PEEK,etc

Metal powder, such as aluminum alloy, titanium alloy, stainless steel, mold steel

Forming precision : ±0.2mm(L≤200mm)

Layer thickness : 0.08-0.3mm

Product characteristic : Good mechanical properties, high strength.

Some Common Quetions about Rapid Prototyping

What benefits can rapid prototyping bring to us ?

- Reduce R&D costs and promote product innovation. Rapid prototyping enables fast and precise manufacturing of parts of any complex shape, realizing “free manufacturing” of parts.

- Simplify development process and shorten product development cycle. Rapid prototyping can directly accept design ( CAD ) data without preparing any molds, tools and tooling fixtures, and quickly manufacture samples, molds or models of new products.

- Personalized product customization, small batch production, increased design freedom.

Why did we add the rapid prototyping process?

Because in working with our customers, many of them ask us if we have rapid prototyping process. Some of them have a direct need for rapid prototyping work. Some want to know whether their new product design is reasonable.

What are the most common plastic materials used in rapid prototyping processes?

PLA, ABS,PA(nylon),PC, Filamentous or Powdery

What are the most common metal materials used in rapid prototyping processes?

Aluminum alloy (AlSi10Mg) Stainless steel (316L ) Mold steel (CX) Titanium alloy (Ti6Al4V)

What is the minimum order quantity ? How long to finish ?

A single piece can be printed. Print cycle 3-5 days.

Contact Us Now

If you are looking for a Chinese supplier of rapid prototyping, SANON will be your very good choice. Instant communication, high quality and fast delivery will get your project started and completed smoothly.