Your One Stop Aluminum Die Casting Company

Our Aluminum Die Casting Services

SANON CASTING is a professional aluminum die casting company in China that has been engaged in aluminum die casting for more than 20 years. We can provide professional, economical and efficient one-stop solutions for different aluminum die casting projects, from tooling making to packaging.

Especially in mold making, we have more than 10,000 aluminum die casting mold design and manufacturing experience. At the same time, we have our in-house mold design team and mold making workshop. The molds we make have higher precision and service life (more than 120,000 times). This makes us very proud!

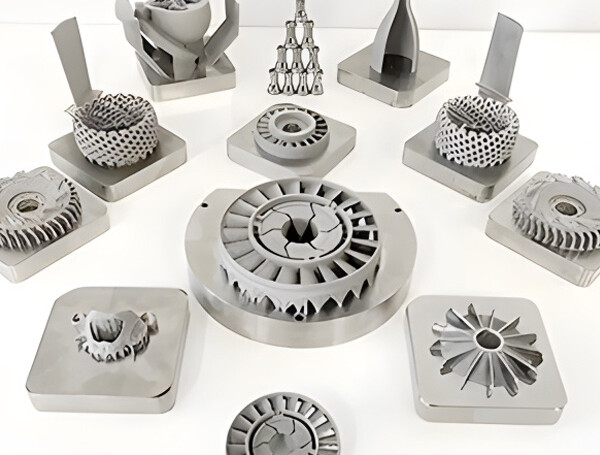

- Rapid Prototyping

- Mold Making

- Die Casting

- CNC Machining

- Surface Finishing

After you have completed the product design, we have two ways to help you quickly get feedback on the product design, and to evaluate and justify the feasibility of the product design.

3D printing: Lowest cost, fastest delivery, suitable for all kinds of metals and plastics.

CNC machining: Our lathes, milling machines, CNC machining centers, and experienced operators can get your precision parts to you faster.

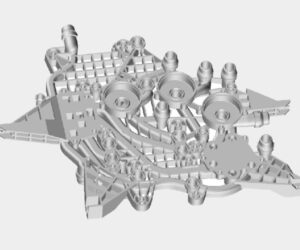

Die casting molds determine the shape, tolerances, surface and internal filling of the part with molten metal. Dies are critical in your aluminum die casting project, so when you are looking for an aluminum die casting manufacturer, you’d better choose one with a mold making shop, especially if your parts are complex or your die casting project is urgent.

SANON CASTING has 22 years of experience in die casting mold manufacturing, which is our earliest business. We have our own mold shop and have done 10000+ die casting molds for different industries. Mold design experience is our great advantage, moreover, we also provide free mold modification and maintenance.

As a professional aluminum die casting manufacturer, we are proficient in 3 different aluminum die casting processes: High Pressure Die Casting (HPDC), Low Pressure Die Casting (LPDC) and Squeeze Casting. These 3 die casting processes can meet almost any of your aluminum die casting project needs.

HPDC: For light weight, thin walled, complex shapes, precision, large volume aluminum castings;

LPDC: For heavy, thick walled, simple shapes, high strength aluminum castings;

Squeeze Casting: For complex shapes, precision, high air tightness, high strength aluminum castings.

If a die casting manufacturer does not have its own CNC processing workshop, it will be difficult for them to ensure the delivery time and quality of molds and parts. But at SANON you don’t have to worry about that.

We have our own lathes, milling machines and CNC centers, which are dedicated to our mold making and die casting processing. This ensures that we have a fast and stable delivery time that is not affected by external factors.

Our CNC machining experience is more than 12 years, and our machining accuracy can reach 0.01mm. we are capable of both large mold making and precision parts machining.

SANON has specialized surface finishing workshop for grinding, shot blasting and polishing. We can meet most of the surface treatment requirements for aluminum die casting parts, which can give your parts a better appearance.

If you have more surface requirements, our outsourced suppliers that we have worked with for many years can provide the following surface finishing processes:

Sandblasting, anodizing, powder coating, electroplating (chrome plating), electrophoresis.

Our Aluminum Die Casting Capabilities

Aluminum High Pressure Die Casting

- Material: A319, A356, A535, A369, A380, ADC12 or as your requirement

- Wall Thickness: 2mm-20mm

- Weight: 5g-10kg

- Accuracy: ±0.01mm

- Mold Life: 120,000 times

- Surface Roughness: Ra3.2–Ra1.6

- Surface Treatment: Polishing, shot blasting, sand blasting, anodizing, powder coating, electroplating, electrophoresis, etc.

- ISO 9001 and IATF16949 certified. Strict quality management system. Familiar with PPAP requirements.

- Specialized in casting auto parts.

Aluminum Low Pressure Die Casting

- Material: A356, ZL101, ZL104, ZL107 or as your requirement

- Minimum Wall Thickness: 5mm

- Maximum Size: 2800mm*1200mm

- Weight: 1kg-500kg

- Mold Life: Permanent

- Surface Roughness: Ra3.2–Ra1.6

- Mainly used for casting large-sized aluminum parts with high strenth, high air tightness and high requirements.

- Castings can be heat treated.

- Suitable for auto parts, truck parts, electrical accessories, high-end equipment, etc.

- Material: A356, A356.2,AlSi9Cu3

- Wall Thickness: 4mm-40mm

- Weight: 10g-20kg

- Accuracy: ±0.01mm

- Mold Life: 120,000 times

- Surface Roughness: Ra3.2–Ra1.6

- The end of common aluminum die casting defects.

- Castings can be heat treated and welded.

- Low porosity, high density, high strength (tensile + yield), high hardness, high air tightness.

- Ideal for automotive die casting parts, electric car parts.

We use the above three processes to provide you with precision aluminum die casting parts of different sizes, shapes, wall thicknesses, weights, tolerances, and properties. At SANON, you will always get a correct and efficient solution. As an aluminum die casting supplier, this is the fundamental reason why we are able to continue to grow.

Contact us to custom your aluminum die casting components! We have the ability to provide you with the best aluminum die castings within your budget!

Our Aluminum Die Casting Parts

-

Squeeze Casting Parts

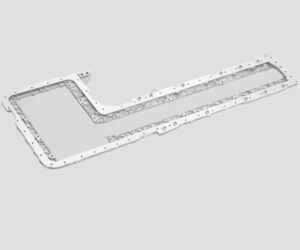

Aluminum Die casting | Squeeze Casting EV Battery Housing

-

Squeeze Casting Parts

Aluminum Die Casting | Squeeze Casting EV Part

-

Die Casting Electric Vehicle Parts

Electric Vehicle Die Casting | Squeeze Casting Inverter Housing

-

Die Casting Electric Vehicle Parts

Aluminum Die Casting | Squeeze Casting EV Coolant Side Manifold

-

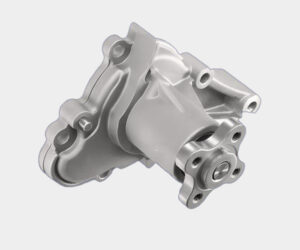

Die Casting Automotive Parts

Aluminum Die Casting | Squeeze Casting Auto Parts Water Pump

-

Die Casting Automotive Parts

Aluminum Die Casting | Squeeze Casting Auto Parts Oil Pump

-

Die Casting Automotive Parts

Aluminum Die Casting | Squeeze Casting Auto Control Arm

-

Die Casting Automotive Parts

Aluminum Die Casting | Squeeze Casting Valve Cover

Why Choose SANON as Your Aluminum Die Casting Manufacturer?

1. Experienced. SANON has more than 20 years experience in aluminum die casting and has provided manufacturing services for aluminum die casting projects in different industries.

2. One-Stop Aluminum Die Casting Solution. From mold making to surface treatment, we can provide professional service. We are proficient in die casting and also have professional surface treatment partners.

3. Master The Core Technology. Mold making is the most critical part of the die casting process, and this is where we excel. Our in-house mold making can quickly solve all mold problems.

4. Strong Production Capacity. 6 professional engineers, 160 tons to 1100 tons die casting machines, more than 20 lathes, milling machines and CNC machines, these combinations can make your aluminum die casting project executed quickly and get the best result.

5. Competitive Pricing. We will provide you with the best product quality and die casting service within your budget.

Industries We Serve

SANON provides reliable aluminum die casting services for different industries, including automotive, motorcycle, marine, telecommunication, medical, electric motor, household appliances, LED lighting and new energy industries. Many high-performance, high-precision and durable aluminum die casting components are also used in aerospace, medical and other demanding industries.

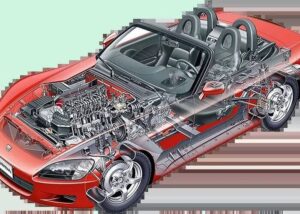

Automotive Die Casting

Automobile engine parts, engine block, cylinder head, valve bracket, electric parts, motor end cap, pump housing, reflector bracket, mirror bracket, cross member, body B-pillar , wiper parts, air-conditioning compressor housing, etc. Currently, automotive lightweighting is becoming more and more popular, and you can custom your own auto parts!

Electric Car

Battery enclosure assemblies, battery tray,motor housings, socket shell, AC compressor, heat sink, controller enclosure, reduction housing, etc. Meanwhile, you can custom your unique electric vehicle parts!

Machine Parts

The aluminum die casting process is widely used in the production of various industrial equipments and parts. For example, motor, aviation, ship, home appliance, medical and other industries.

LED Lighting

Aluminum alloy has light weight, good heat dissipation and beautiful performance, which is widely used in LED lighting industry. Lamp housings, lamp holders, heat sinks, sockets and many other LED parts are made of aluminum die-casting.

Other Industries Parts

SANON is proficient in aluminum die-casting, permanent mold casting, and squeeze casting. In addition to the above 4 industries, we have also served the new energy, motorcycle, medical, household industries and other industries. Our advanced equipment and experienced engineers can meet the casting needs of customers from any industry.

Aluminum Die Casting Alloys

Die cast aluminum alloy has good casting performance and can form parts with complex shapes. We choose high quality materials to provide you with professional aluminum alloy die casting service.

Commonly used die casting aluminum alloys are: A356, A360, A380 (ADC10), A383 (ADC12), AlSi9Cu3, AlSi10Mg and so on.

A356

The A356 aluminum alloy is a casting aluminum alloy that boasts excellent overall performance. In addition to having good casting properties and the ability to cast thin-walled and complex shaped castings, it can achieve a high strength through heat treatment. Typically A356 is used to cast automotive wheels, transmissions, and housing products.

A360

A360 has excellent pressure resistance and flowability. Its relatively high silicon content provides high corrosion resistance and high strength even at high temperatures. It is suitable for die-casting cylinder head covers, sensor brackets, cylinder blocks, and other parts.

A380 (ADC10)

The A380 aluminum alloy benefits from excellent fluidity, air tightness, and heat crack resistance. It shines when it comes to machining and combines casting, mechanical, and thermal properties perfectly. A380 is used to cast a wide range of products from motor equipment chassis, engine brackets, and gearboxes to furniture, generators and hand tools.

A383 (ADC12)

The ADC12 aluminum alloy is easy to mold with a good heat dissipation making it suitable for thin-walled products. It is most commonly used in Japan and China. By adding Cu, Mg, and Mn, the overall performance of ADC12 is made better in all aspects.

Aluminum Die Casting Advantages

One of the main advantages of aluminum die casting is the ability to produce near-net shape parts in just a few seconds. While aluminum die casting is typically more expensive, it is faster and more cost-effective when producing parts in large quantities. As a result, this advantage has made aluminum die casting one of the most popular processes, and many industries take advantage of it.

Here are some of the other advantages of aluminum die casting:

Excellent surface finish

Fewer impurities

Wide range of applications

Ability to integrate metal inserts

Contact Us Now

If you are looking for a reliable aluminum die casting company, then SANON will be your best partner in China. We have 20 years of experience in aluminum die casting, and we can also do CNC machining, surface treatment, etc. SANON can provide you with a one-stop solution.