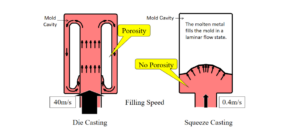

Types of Casting Process

This article summarizes 9 different casting processes and details the materials, molds, processes, advantages, disadvantages, common products, etc. for each process. If you want to learn about the different casting processes, this article will help you a lot.