Gravity Casting Supplier in China

Definition

Gravity casting is a metal casting process in which molten metal is poured into a mold and then cooled to form it. It is sometimes referred to as gravity casting.

The molds used in permanent mold casting are mostly made of steel or iron, which can be reused many times, and a casting is obtained every time the molten metal is poured.

Molds made of H13 steel can be used 150,000-200,000 times. The improved H13 steel can be used more than 400,000 times, so this casting process is called permanent mold casting.

Capabilities

Type: gravity, slush, low-pressure, and vacuum.

Shape: simple and complex

Weight: 100g-80kg

Tolerance: ± 0.38mm

Surface finish – Ra: 120 – 250 μin

Max wall thickness: 2.5-50mm

Lead time: weeks

Material: aluminum alloy

Advantages and Limitations

Advantages

- Higher mechanical properties. The tensile strength of permanent die casting aluminum parts is about 25% higher than that of sand casting, and the yield strength is 20% higher than that of sand casting.

- Higher dimensional accuracy and smoother surface.

- Permanent mold casting is more productive than sand casting. The sand mold can only be cast once, and must be reshaped after the casting is obtained, while the mold cast by the permanent mold can be reused tens of thousands of times.

- The process is simple, the service life of the mold is long, it is easy to realize mechanization and automation, and it is suitable for mass production.

Limitations

- The mold cost is high. If you are on a tight budget or the project quantity is a small batch, it is not suitable for permanent mold casting.

- Material limitations. The melting point of molten metal must be lower than that of the mold, so the permanent mold casting is generally used for aluminum alloy, zinc alloy, and magnesium alloy casting, and it is less used for copper alloy casting, and even less for ferrous metal casting.

- Size restrictions. Due to the limitation of mold size and cavity processing equipment, if your castings are large in size, then don’t choose permanent mold casting, which is mainly used to produce small and medium-sized parts.

Therefore, when deciding to adopt a permanent mold casting process, the following factors must be considered comprehensively:

- The casting shape and weight must be suitable.

- There must be a large production batch.

- Whether the production task can be completed within the deadline.

Gravity Casting Steps

- Preheat the mold. Unpreheated metal shapes cannot be poured, otherwise defects such as cold shuts and porosity will occur. Generally, the preheating temperature is not less than 150°C.

- Applying coating. Coat the surface of the mold cavity with a layer, which regulates the cooling rate of the casting, protects the mold and extends its service life, and promotes part removal. The coating should be fire resistant.

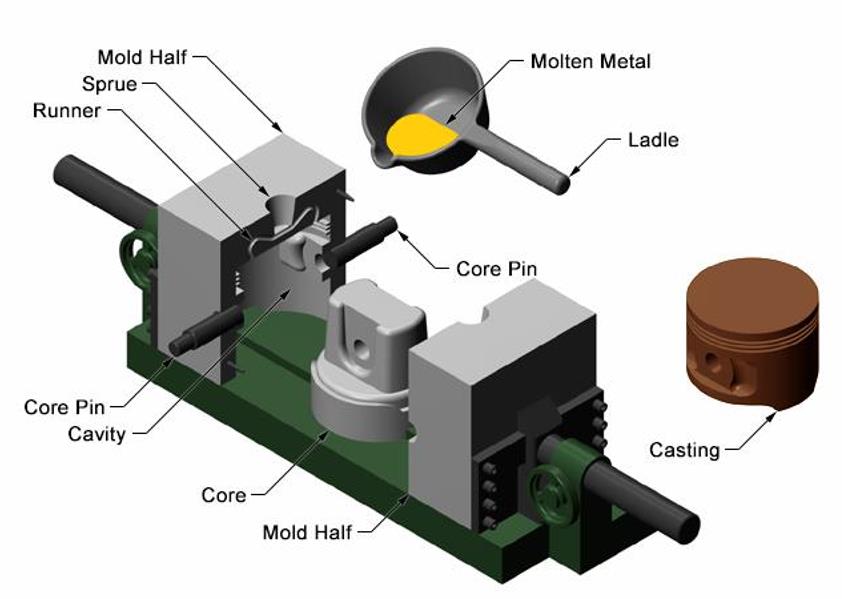

- Mold assembly. The mold consists of two half-dies and the core. The cores are usually made of iron or steel, but sand cores are also used when casting thin-walled complex parts. The core is inserted between the two half-molds.

- Pouring. The molten metal is poured into the fixed mold. At this point, the pouring temperature should be noted. The pouring temperature of aluminum is generally 680-740°C. During the pouring process, the liquid flow should be as smooth as possible.

- Cooling. Allow the molten metal to cool and solidify in the mold.

- Open the mold. After the metal has solidified, open the two half molds and remove the casting.

- Trimming and machining. Remove the excess from the casting and then the surface treatment is carried out. Heat treatment and CNC machining can also be performed if required.

Your Trusted Gravity Casting Supplier

If you have a project for aluminum permanent mold casting, please contact us. We have been engaged in aluminum casting for more than 20 years, so we are very familiar with the permanent mold casting process. We will be your excellent project partner.